PREVIOUS EXPERIENCES

Aircraft Engine Test cell Maintenance

- Engine Test Cell Calibration/Verification

- Engine Test Cell Control Maintenance.

- VMS Model MPI 320 Maintenance

- NEFF System 620 Maintenance

- Engine Test Cell Control Room – Cenco.

- Engine Test Cell Fuel System Maintenance.

- Engine Test Cell Control Room – Cenco. (Upgrade Project)

- FS-Elliott / Air Compressor Maintenance.

- Engine Test Cell Cranes System

Aircraft Component Test Equipment Maintenance

- IDG Test Stand

- Spray Center A2000 and Robotic -6

- APU Test Stand Maintenance.

- Rotary Actuators Universal Test Stand

- Aircraft Balance Machine

- GE 2000 CNC Maintenance.

- GE DC-200 Maintenance

- Ovens

- CNC Lathe Machines.

- Grinders Machines.

- Aircraft Coolant Service Cart

- Hydraulic Mule Machines.

- Milling Machines.

- Plasma Cutting Machines

- HMU Test Stand

Buildings / Hangars Facility management Services

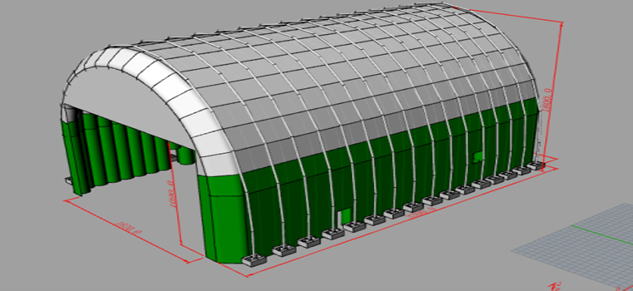

- Inflatable Hangar – Electrical

- Inflatable Hangar – HVAC

- HVAC Systems / Air Washer System.

- Fire Pump House.

- Lighting System.

- Motor Control Centers (MCC)

- Hangar Crane Systems.

- Hanger Doors Support.

- Air compressors.

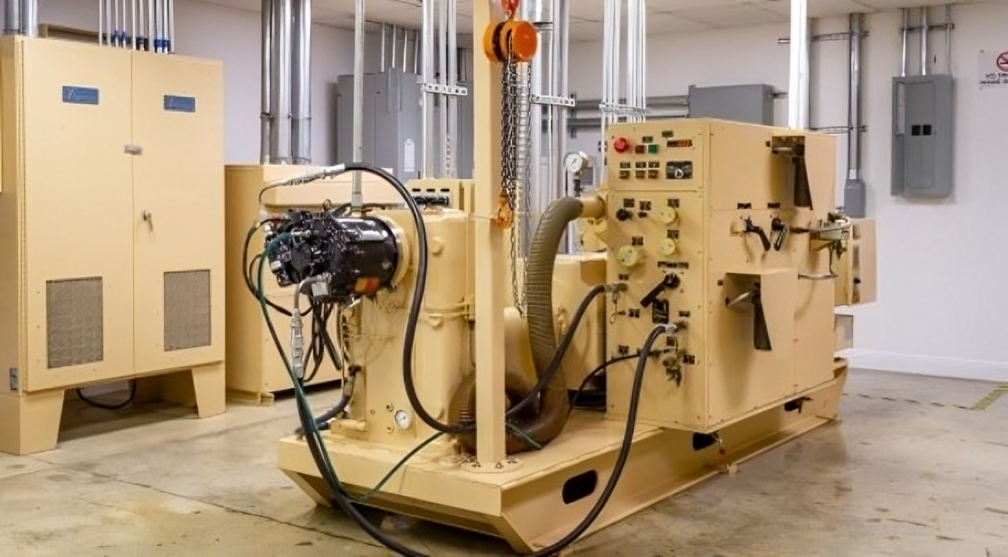

- Generators / UPS.

Aircraft GSE Equipment Maintenance

- Techuert Escalator

- Universal Tripod Jack Test Stand

- Universal Axle Jack Test Stand

- Malabar Single Stage Axle Jack

- Malabar Three Stage Axle Jack

- Tow Tractors

- Transporter Trepel Trans

- VVIP Lounge Maintenance

- Auto Diesel GPU

- Lift-A-Lift Platform

Ensures functionality, comfort, safety and efficiency of operation throughout:

- 24×7 Emergency support

- Unlimited on-call support

- Preventive maintenance

- Renovation Projects